Prototype injection molding performs an important function in product improvement by linking the idea and large-scale manufacturing phases. Throughout this section of manufacturing, designers and engineers check and refine their designs earlier than transferring on to full-scale manufacturing. A powerful grasp of the basics of prototype injection molding can vastly enhance the effectivity and success of the manufacturing course of.

Exploring the Fundamentals of Prototype Injection Molding

Prototype injection molding strategies in as we speak’s manufacturing processes entail producing a predefined amount of parts to evaluate design components and materials picks. This strategy gives a solution to decide each the performance and visible attraction of the elements into account. It permits stakeholders to deal with any challenges at an early stage of improvement, thereby conserving time and sources within the grand scheme of issues.

Benefits of Utilizing Prototype Injection Molding

Prototype injection molding provides many advantages, making it a compelling alternative for companies. This system helps manufacturing bills by recognizing design flaws in mass manufacturing. It additionally hurries up the time-to-market course of by enabling iterations. This adaptability permits groups to make knowledgeable selections, leading to improved merchandise.

Selecting the Applicable Supplies

Choosing the supplies is important in making certain efficient prototype injection molding outcomes. The selection of fabric considerably influences the half’s efficiency, look, and value of manufacturing. Standard choices include thermoplastics corresponding to ABS, polycarbonate, and polypropylene. Every type of material possesses traits, underscoring the significance of greedy the required specs for attaining the very best outcomes.

Components to Contemplate When Creating Molds

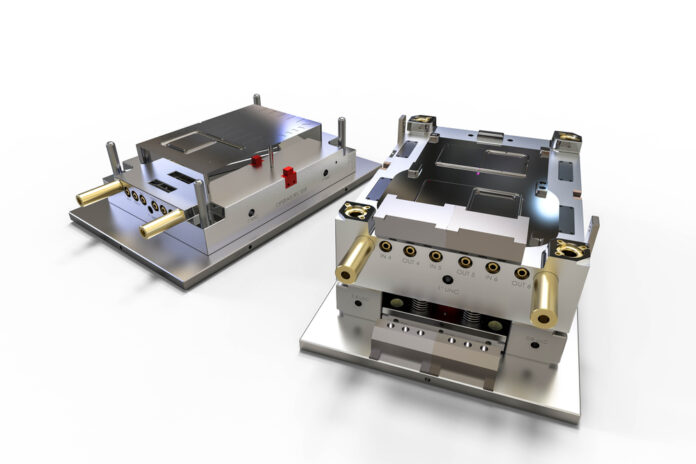

Creating the mould itself is essential within the phases of the prototype injection molding manufacturing course of, with concerns for half geometry intricacy and tolerances enjoying a task in mould design choices. The simplification of the design can result in time and value financial savings; nonetheless, striking a balance between simplicity and assembly useful and aesthetic necessities is important.

Using 3D Printing for Creating Molds

Technological progress has introduced new strategies for designing molds to the forefront of innovation. In terms of creating mould prototypes, a notable advance includes the utilization of 3D printing. This methodology gives a budget-friendly choice in comparison with mould manufacturing strategies, enabling swift modifications and refinements that help a versatile improvement course of.

Components to Contemplate When Budgeting

In terms of prototype injection molding, prices are often affordable. Some elements affect the full bills, together with tooling bills, supplies chosen, and the manufacturing quantity. By optimizing these features, corporations can strike an excellent stability between high quality and price range. Getting steerage from professionals might be helpful in managing these monetary concerns successfully.

Optimizing the Manufacturing Process

Guaranteeing the manufacturing course of runs easily is essential for prototype injection molding operations. Incorporating manufacturing strategies can improve operations by lowering waste and refining workflows. This methodology boosts effectivity and in addition promotes eco-friendly practices.

Exploring and Verifying Prototypes

After the creation of prototypes is accomplished with care and a focus to element, the testing and verification process turns into essential to make sure that the parts meet the desired design necessities and function as deliberate. Testing might embody a variety of assessments, together with thermal or chemical evaluations, based mostly on the particular utility. A complete validation process is essential in instilling confidence within the design earlier than advancing to large-scale manufacturing.

Environmental Components to Contemplate

The deal with sustainability is growing throughout the manufacturing sector, together with prototype injection molding processes. Selecting supplies and enhancing manufacturing strategies assist decrease the environmental footprint. Incorporating recycling and environment friendly waste administration methods additionally helps the overarching sustainability aims. This technique advantages the setting and in addition boosts model picture and credibility.

Collaborating with Seasoned Producers

Working along with knowledgeable producers can affect the outcomes of prototype injection molding endeavors. Skilled companions present views and technical know-how whereas granting entry to cutting-edge applied sciences. Creating connections with producers ensures a journey by way of manufacturing and leads to a top-notch remaining product.

Wrapping Up

Prototype injection molding is essential to efficiently turning ideas into actual merchandise. Companies can confidently navigate the method by contemplating key components like supplies and design whereas contemplating price elements. Prioritizing effectivity together with testing and sustainability results in outcomes in the long run. A well-crafted prototype injection molding process establishes a basis for easy mass manufacturing, opening doorways to realize success available in the market.